•Business: Automotive Supplier, ArvinMeritor is the system supplier of the front axle and suspension for a new series of Class-8 tractors.

•Challenge: A prototype vehicle was tested on public roads and proving grounds and a front wheel shimmy problem was observed at specific vehicle speeds and road conditions. Vehicle dynamics simulation and analysis were requested in order to understand the shimmy phenomenon and seek acceptable modifications to the design of the front axle and suspension.

•Front wheel shimmy occurs at 6-7 Hz, and sustained at vehicle speeds greater than 30 mph

•Running modes analysis shows that shimmy is a coalescence of frame twist mode, frame lateral bending mode, engine yaw mode, axle roll mode, axle lateral mode, and steering system vibration mode

•Simulation objectives:

•Reproduce shimmy phenomenon observed in the field

•Develop an understanding of the shimmy phenomenon

•Determine the sensitivity of shimmy propensity to various front axle and suspension design parameters

•Recommend modifications to the design of the front axle and suspension

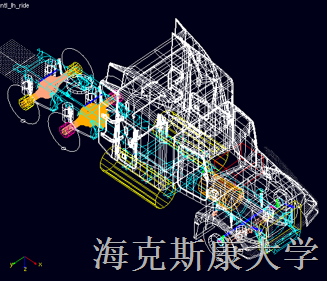

•Solution: Sensitivity analysis with MSC.ADAMS truck model with

•Truck frame: modal neutral file from MSC.Nastran

•Front suspension: mechanical leaf spring (beam elements), air spring (nonlinear force-deflection curve), and shock absorbers (nonlinear force-velocity curves)

•Rear suspension: trailing arm (beam elements) and air springs

•Steering system: pitman arm, drag link, steering arm, tie rod arms, cross tube

•Cab, engine, transmission: rigid bodies

•Tires: Pacejka magic formula tire model

•Value: All factors were found to be significant to wheel shimmy propensity

•Kingpin friction was the most significant factor – increasing kingpin friction helps reduce wheel shimmy propensity

•Interaction between vehicle speed and tire relaxation length (negative damping effect) was a dominant contributor to wheel shimmy

•2, 3, and 4-factor interactions were present – it is difficult to make general statements regarding the effect of any one specific factor on shimmy propensity

•Simulation allowed to suggest following design changes to the prototype vehicle:

•Increase kingpin friction •Increase length of steering arm

•Use tires with higher lateral stiffness (bias ply tires)

•Reduce caster angle

•Increase suspension lateral stiffness

Reference: “Wheel Shimmy in Heavy Duty Trucks: Using Designed Numerical Experiments to Determine a Robust Solution”, Ragnar Ledesma, Principal Engineer, Commercial Vehicle Systems, ArvinMeritor, Inc. Americas VPD 2004 conference